TWO-PHASED CONSTRUCTION

Power plant projects are complex and expensive, especially for developing countries. Financing them can be a challenge, even with the excellent payout of TransVit installations.

For this reason, TVI has developed a Two-Phase project approach, primarily for reducing perceived risk. It also allows time to improve development of infrastructure including the reliability of waste delivery, which is a common issue in developing countries. It also increases the time available for the training of operators, and improves confidence and ability to obtain investors and bank financing.

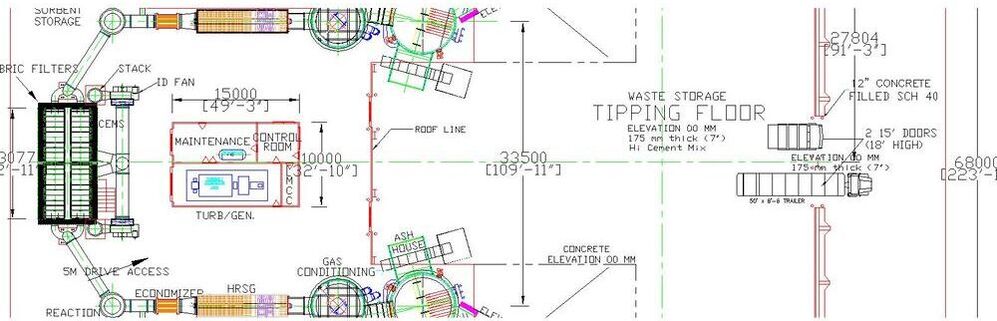

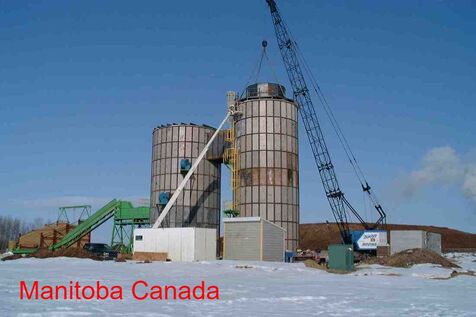

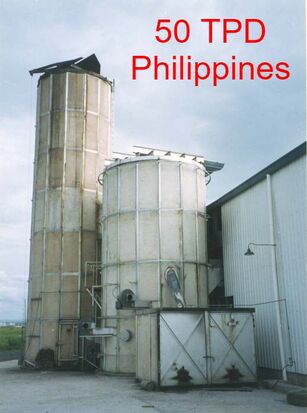

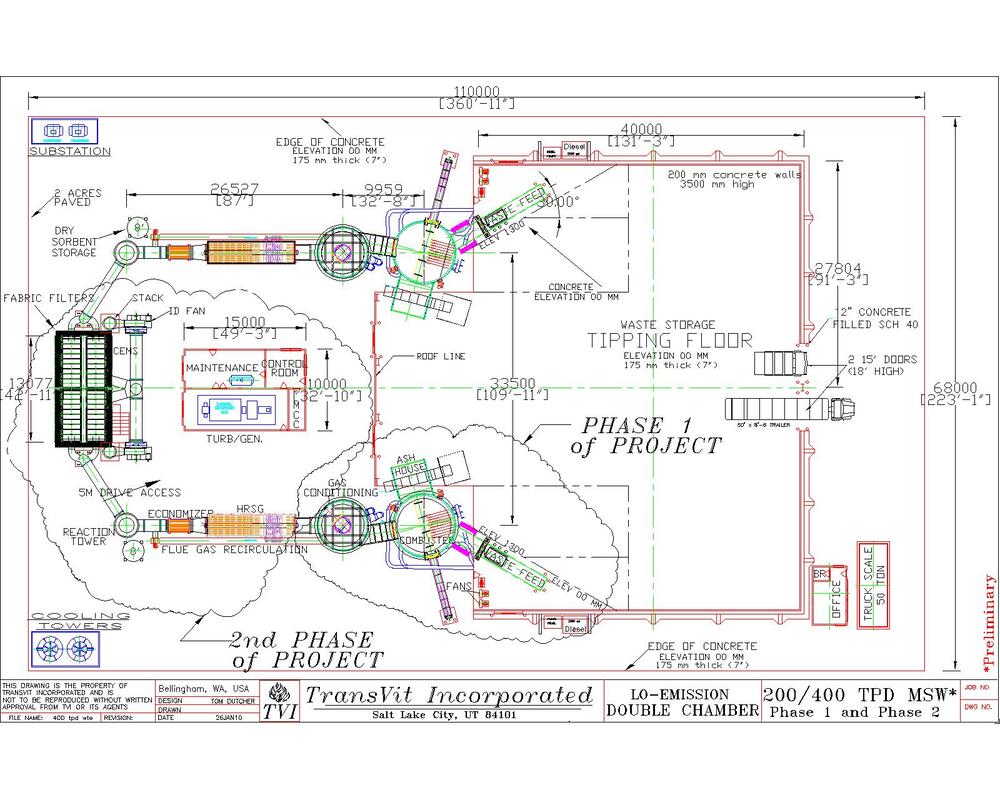

Phase 1, about 15% of total project cost, includes site prep and one 200 ton per day gasifier. Construction of site and gasifier takes 8 to 12 months. In the time following startup of Phase 1, the kinks of reliable waste delivery are resolved and demonstrated, plus gasification of the non-homogeneous waste is proven and optimized, and operators are trained. Significant unknowns are resolved prior to the Phase 2 financing.

Phase 2, the electrical generation, begins soon startup of Phase 1, as successful operation is proven to banks and investors.

Design of Phase 2 will be mostly completed during the construction of Phase 1, and Phase 2 equipment orders and construction can begin quickly for the second 200 tpd gasifier, two boilers, 8 MW turbine/generator, and emission control. Completion will take approximately 18 to 20 months.

Immediately at startup of Phase 2, the cash flow from electricity sales yields an attractive profit in addition to covering operating costs and payout of the financing sources.

Details of these two Phases will be clarified during an initial Feasibility Study.

Power plant projects are complex and expensive, especially for developing countries. Financing them can be a challenge, even with the excellent payout of TransVit installations.

For this reason, TVI has developed a Two-Phase project approach, primarily for reducing perceived risk. It also allows time to improve development of infrastructure including the reliability of waste delivery, which is a common issue in developing countries. It also increases the time available for the training of operators, and improves confidence and ability to obtain investors and bank financing.

Phase 1, about 15% of total project cost, includes site prep and one 200 ton per day gasifier. Construction of site and gasifier takes 8 to 12 months. In the time following startup of Phase 1, the kinks of reliable waste delivery are resolved and demonstrated, plus gasification of the non-homogeneous waste is proven and optimized, and operators are trained. Significant unknowns are resolved prior to the Phase 2 financing.

Phase 2, the electrical generation, begins soon startup of Phase 1, as successful operation is proven to banks and investors.

Design of Phase 2 will be mostly completed during the construction of Phase 1, and Phase 2 equipment orders and construction can begin quickly for the second 200 tpd gasifier, two boilers, 8 MW turbine/generator, and emission control. Completion will take approximately 18 to 20 months.

Immediately at startup of Phase 2, the cash flow from electricity sales yields an attractive profit in addition to covering operating costs and payout of the financing sources.

Details of these two Phases will be clarified during an initial Feasibility Study.