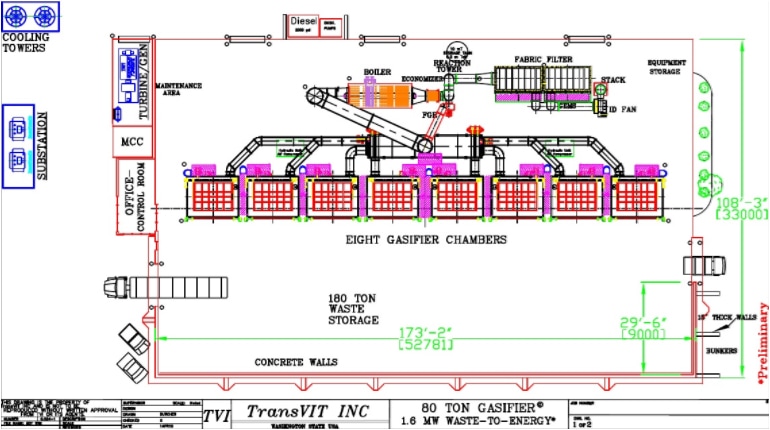

This BATCH design is perfect for smaller applications. Each 10 ton chamber of this BATCH system is loaded full once per day, a 30 minute process. Thereafter, the chamber operates unattended and without disturbance of the waste pile for 23 hours. Emissions and ash quality are the best in the world. The white ash color shows close to 100% complete burnout.

|

Thermal Oxidation is not active, turbulent incineration. It is two stage gasification, using little auxiliary fuel, other than for brief start-up. This batch process of waste reduction integrates slow gasification and long exposure time at moderate temperature, and couples it with a high temperature and excess air secondary chamber. Benefits of this patent pending process are:

The most important operating characteristic of Batch Chambers is the "quiet", low temperature environment within the primary chamber, which minimizes particulate emissions, heavy metals, and noxious gasses. This low temperature chamber results in elimination of slagging glass, reducing system maintenance.

The gasification process occurs in these 10 ton Primary Chambers exposing all waste to a 23 hour treatment period. Inorganic materials such as rock, metals, aluminum, glass, copper wire, and cans never reach a gaseous state since the temperatures in the Primary Chambers are kept below their melting points. Hazardous heavy metal emissions to atmosphere are, therefore, minimized. These unoxidized, inorganic materials remain as ash and are sterilized, cleaned, and in their original material state. They are thereby easily and safely separated later from the ash for recycling. The organic, burnable waste is exposed to 23 hours within the chamber, thereby being almost 100% eliminated. Only white ash remains. |

|